When we think of powder, many of us might immediately picture smooth, round particles—something spherical or rounded in shape. However, for those familiar with Materials Science and Engineering, it’s well known that powders don’t always come in such forms. The shapes of powders often vary significantly, largely influenced by the manufacturing processes used to produce them.

In the field of powder metallurgy, there are several types of powder shapes that students learn about. Some of the most common shapes include rounded, spherical, angular, cubic, and flakey structures. These shapes play a crucial role in determining the powder's behavior and properties for various applications, from sintering to additive manufacturing.

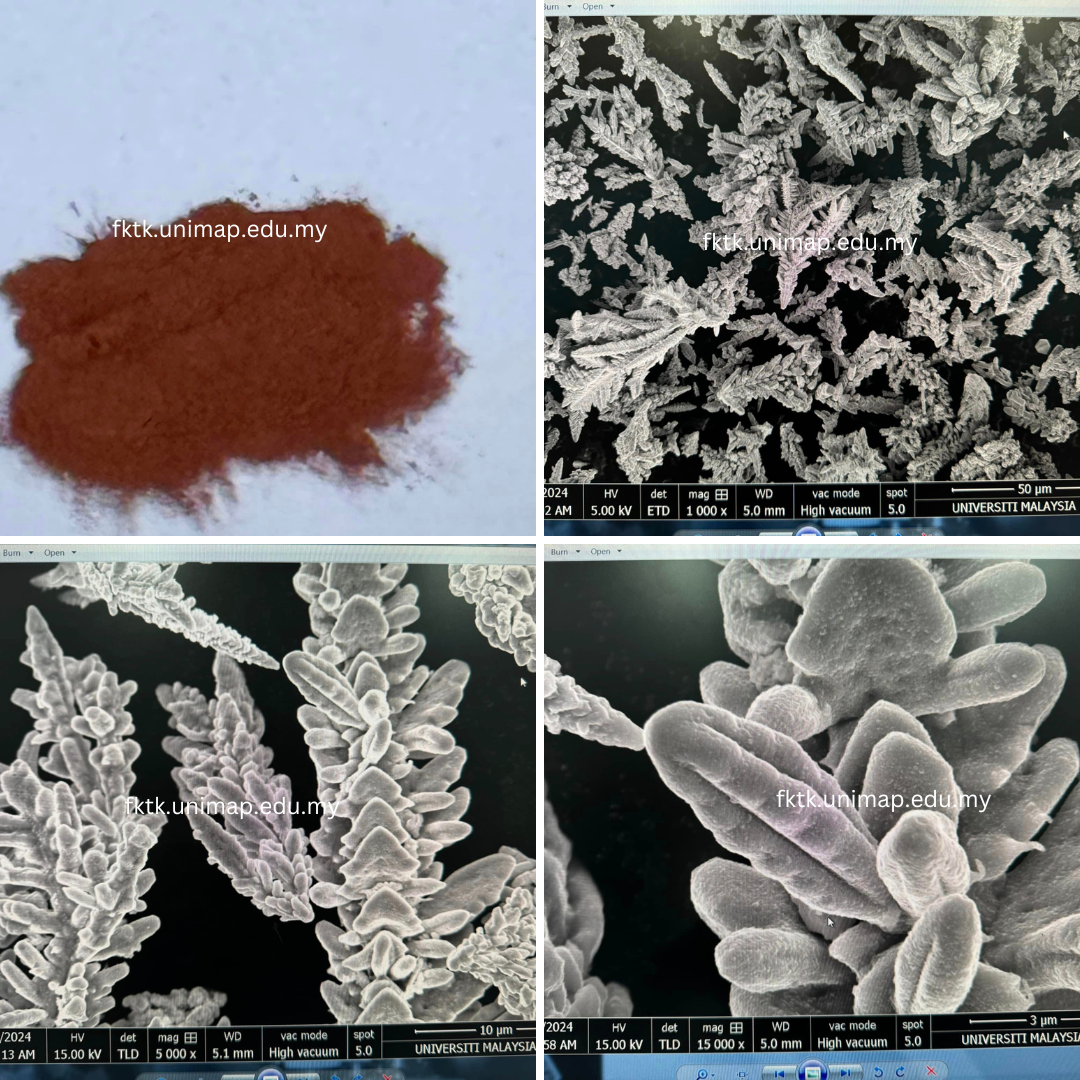

A fascinating example shared by the Faculty of Chemical Engineering & Technology (FKTK), UniMAP, highlights copper (Cu) powder. At first glance, the powder may appear rounded or spherical to the naked eye. Even by touch, it may feel smooth and uniform. However, upon closer inspection through FESEM (Field Emission Scanning Electron Microscope) images from FKTK, the reality is quite different. The magnified images reveal that the copper powder particles exhibit a dendritic structure—resembling a tree-like pattern.

This discovery serves as a reminder that not all powders are created equal and demonstrates the significance of advanced analytical tools in understanding material properties. The intricacies of powder shapes are essential knowledge for students and researchers working in the fields of materials engineering and powder metallurgy.

Stay tuned for more interesting insights into materials science from FKTK, UniMAP, as we continue to explore the world of engineering materials with state-of-the-art technologies!